Biomass Steam Boiler

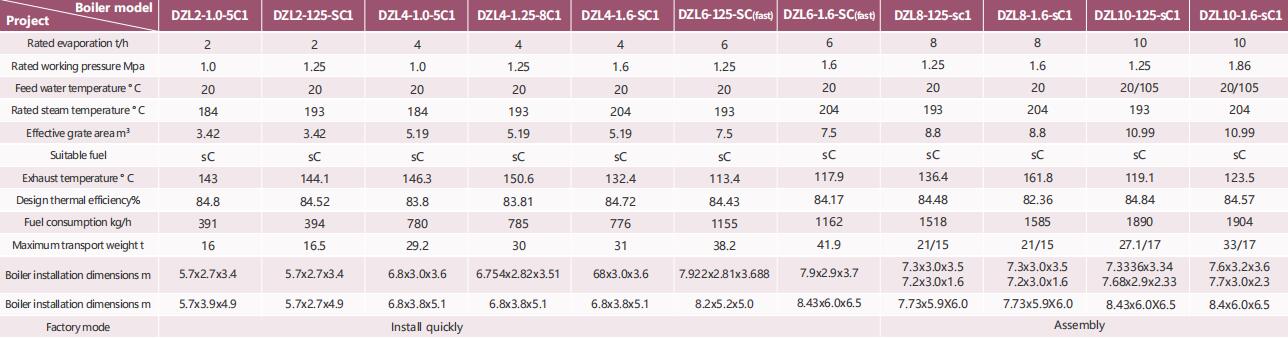

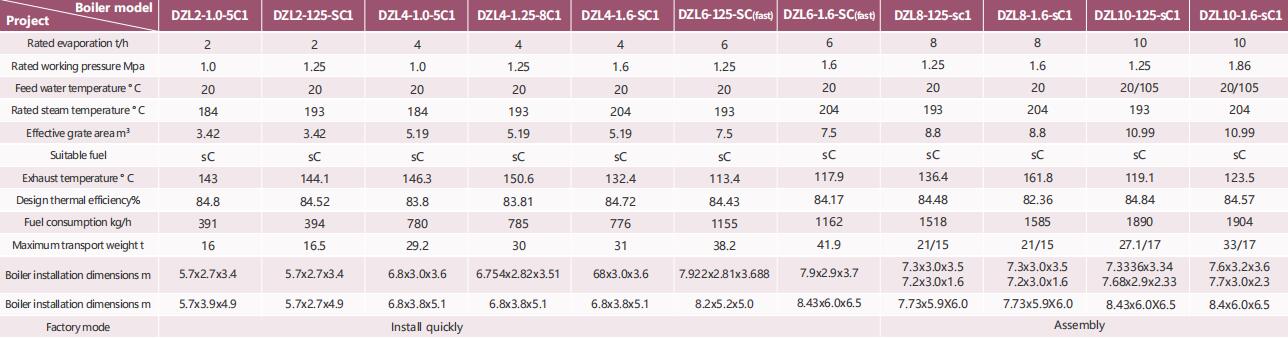

1.DZL series biomass steam boiler

The boiler adopts chain link fire grate, with two-way air intake along the width direction below the grate. There are multiple air chambers on each side, front and back. Each air chamber inlet is equipped with an air volume regulating door. Above the grate is boiler furnace, and there are water-cooled walls around the furnace. The flue gas passes through the economizer and multi-tube dust collector, and finally the soot is discharged into the atmosphere.

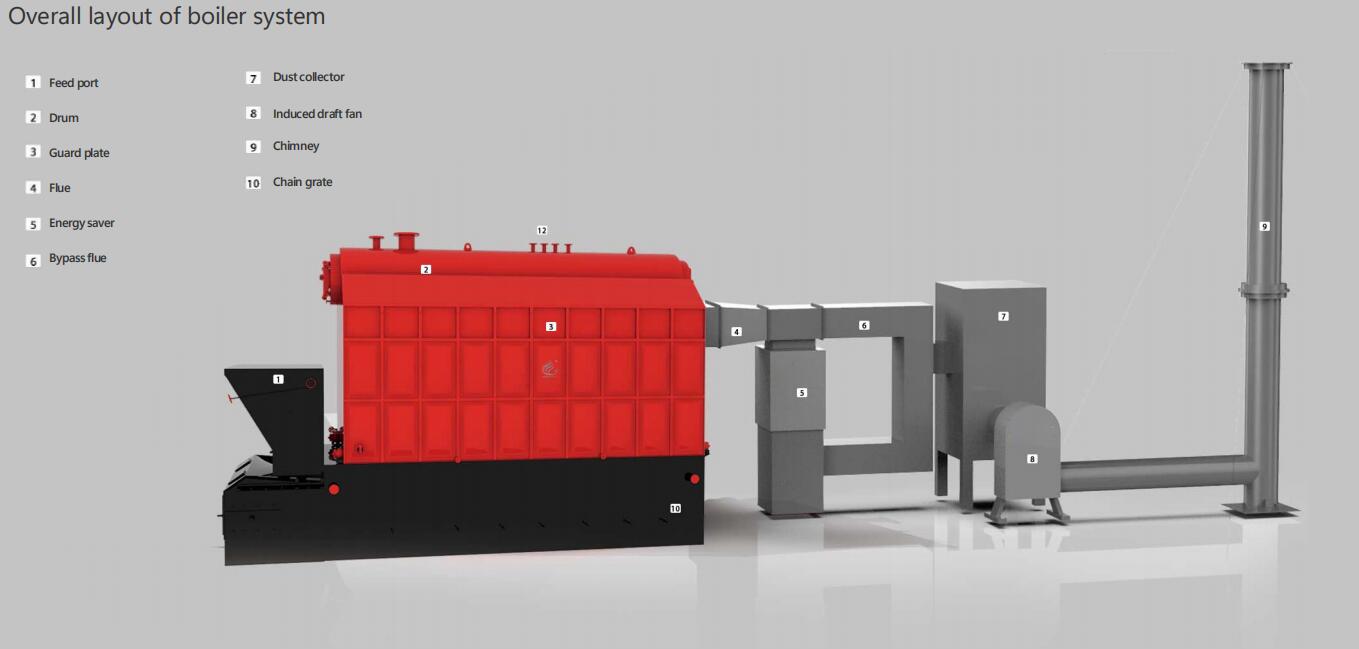

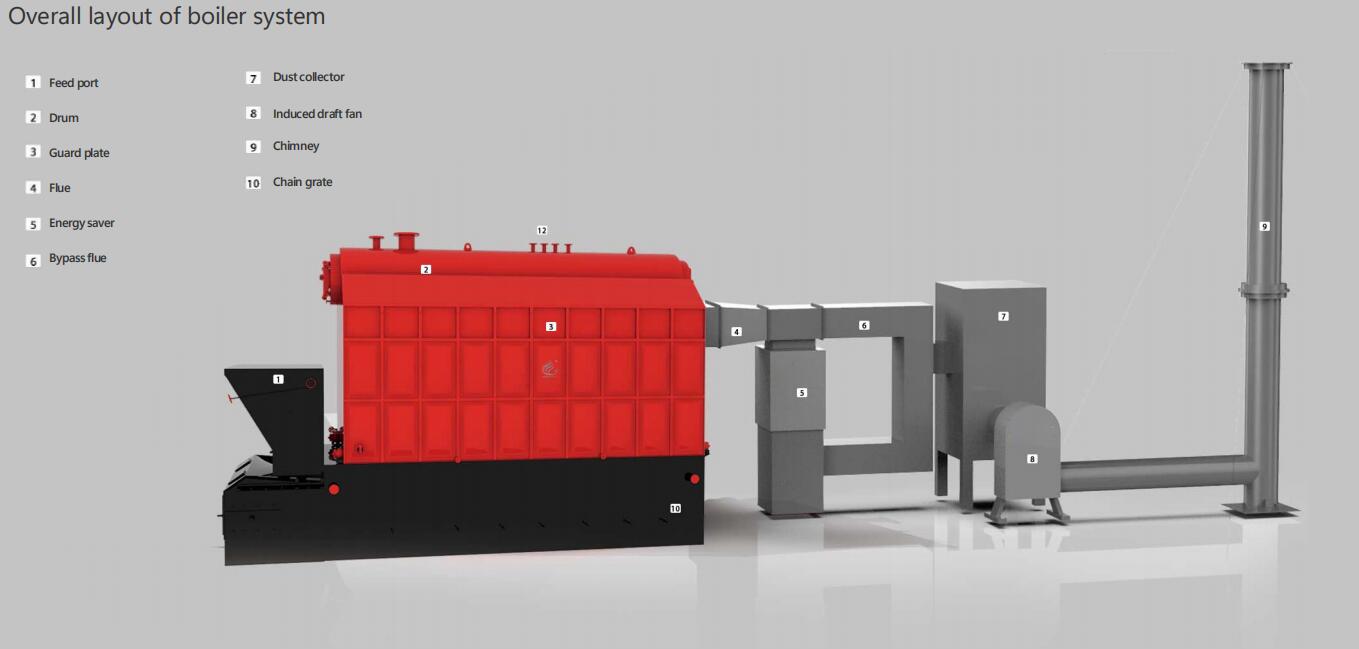

Overall layout of boiler system

- The above effect drawings are typical suggested configurations, not construction drawings, for reference only. The specific configuration is subject to the order content when order placed.

Note: The parameters in the table are for reference only. Due to our company's continuous technological research and development, the technology can be changed without prior notice. The technical parameters are subject to the drawings.

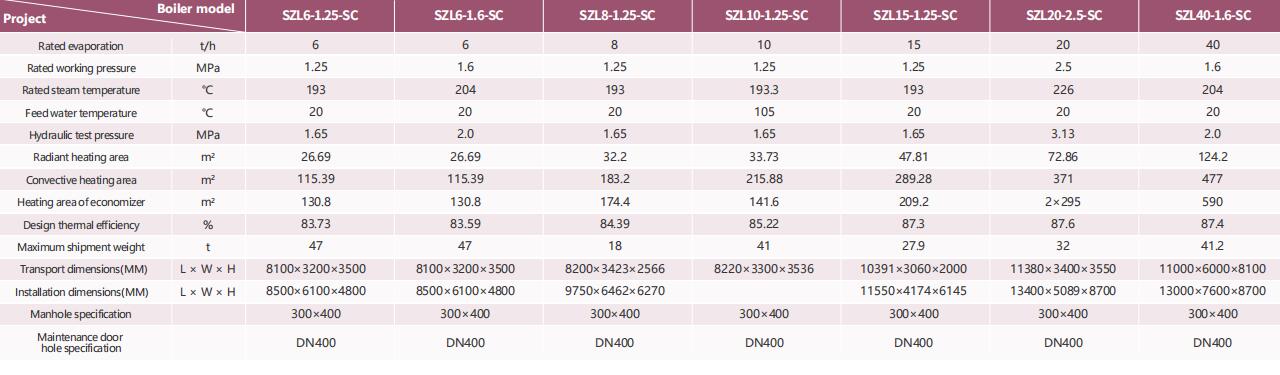

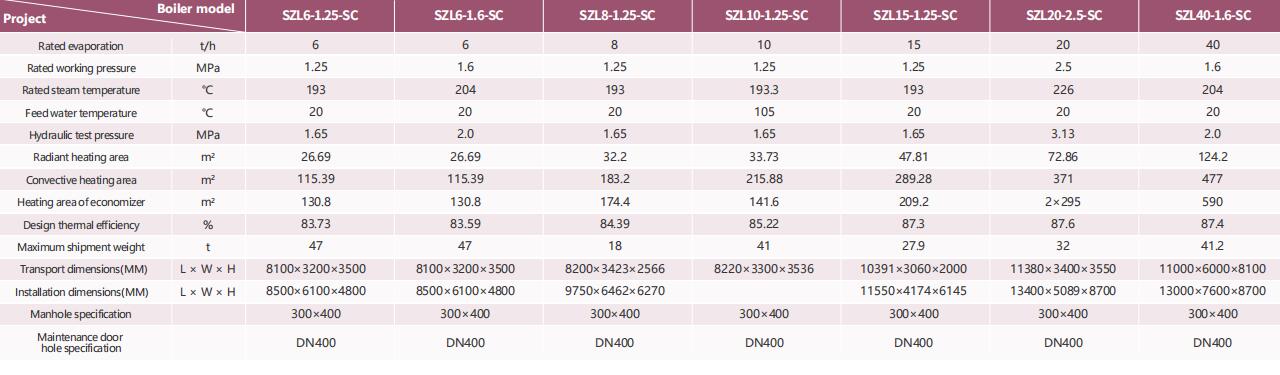

2.SZL series biomass steam boiler

Under the grate, there are two-way air inlets along the width direction. There are multiple air chambers on each side, and each air chamber inlet is equipped with an air volume regulating door. Above the grate, there are water-cooled walls around the boiler furnace. A high-temperature superheater and a low-temperature superheater are arranged in the horizontal flue at the outlet of the furnace, and the temperature of the superheated steam is adjusted by a water jet reducer. At the tail shaft, an economizer and a multi-tube dust collector are arranged along the flue gas flow.

Boiler performance characteristics

- The designed fuel is biomass formed particles, and a very reasonable front and rear arch optimization design is selected. The grate adopts independent air chamber to evenly supply air from both sides and mechanized combustion. This boiler has the advantages of high thermal efficiency, good safety performance, easy installation, use and maintenance, and has broad market prospects and commercial value.

- Design features

The front end of the boiler body is a water-cooled wall arranged around it to absorb the radiant heat of the furnace. The high-temperature flue gas after combustion passes through the convection heating surface to the economizer and air preheater, and finally enters the dust collector and is discharged through the chimney. The feed water has a small flow rate, small flow resistance, high safety factor, and reliable and stable operation in the cast iron economizer tube. The combustion equipment adopts a scale-type chain grate, which has stable and reliable combustion efficiency.

Scope of application of boiler fuel

The designed fuel for this boiler is biomass molding material. The fuel adaptability of this boiler is very good, such as firewood, plywood, rice husk, furfural residue, coal, etc. If the fuel used generates more heat, the output and combustion efficiency of the boiler will be significantly increased. This furnace type is widely used in large and medium-sized enterprises in the fields of chemical industry, light industry, textiles, building materials, automobile manufacturing, coal mines, food, etc., and has been well received by users through practice.

- Safety accessories for boilers

- The upper drum is equipped with two spring full-lift safety valves to ensure that the boiler does not overpressure, and the water level and pressure detection of the boiler are both equipped with on-site display function and remote transmission function.

- Boiler electrical control

- This boiler has automatic control and chain protection functions.

Parameters of SZL series biomass steam boiler

- The above effect drawings are typical suggested configurations, not construction drawings, for reference only. The specific configuration is subject to the order content when order placed.

Note: The parameters in the table are for reference only. Due to our company's continuous technological research and development, the technology can be changed without prior notice. The technical parameters are subject to the drawings.